The Ultimate Guide to Steel Manufacturers in Darwin

The demand for professional steel manufacturers in Darwin has grown considerably in recent years. As more residents and businesses recognize the value of quality service providers, knowing how to identify and select the right professional for your needs has become increasingly important.

In this detailed article, we’ll explore the key aspects of professional steel manufacturers, helping you understand what differentiates quality providers from the competition and how to ensure you receive the best possible service in the Darwin region. We’ll discuss important factors to consider, common pitfalls to avoid, and strategies for finding the right professional partner.

Throughout this article, you’ll discover practical tips, industry insights, and expert recommendations that will empower you to make informed decisions about steel manufacturers. We’ll examine the key qualities that define exceptional service providers, discuss pricing considerations, and highlight the advantages of working with local professionals who understand the unique characteristics and requirements of the Darwin market.

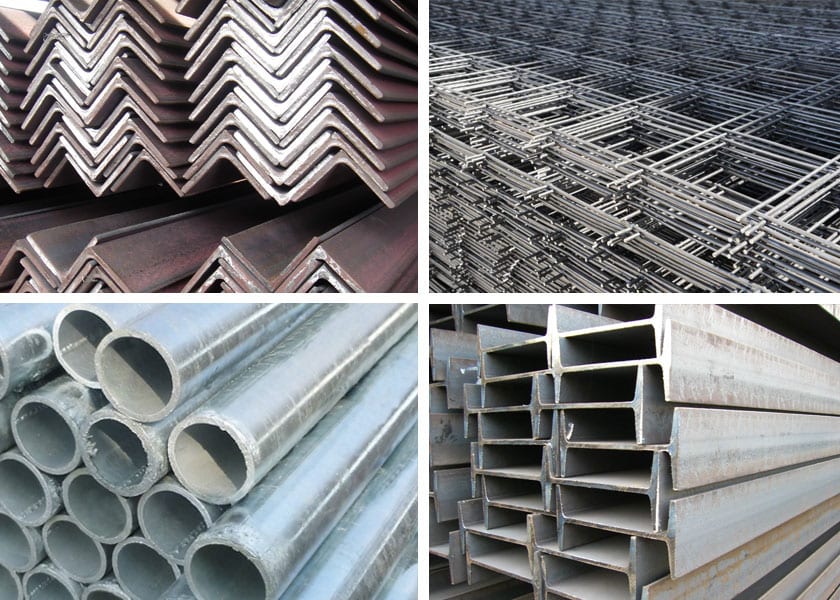

Understanding Steel Manufacturers Services in Detail

Steel Manufacturers encompasses a diverse range of specialized tasks and expertise that require professional knowledge, training, and experience to execute properly. In Darwin, the local climate conditions, regulatory environment, and specific regional factors all play important roles in how these services are delivered and what approaches work best for achieving optimal results.

Professional steel manufacturers providers bring invaluable expertise to every project they undertake. They possess deep understanding of the unique requirements specific to the Darwin area, including local council regulations, building codes, environmental considerations, and industry best practices that ensure quality outcomes. This specialized local knowledge is particularly valuable when it comes to completing work efficiently, meeting all compliance requirements, and delivering results that stand the test of time.

Working with experienced professionals also means gaining access to the right tools, equipment, and modern techniques that may not be available to general contractors or DIY approaches. Reputable steel manufacturers providers invest in professional-grade equipment and stay current with the latest industry developments, technologies, and methodologies. They maintain the necessary licenses, insurance coverage, and certifications to protect both themselves and their clients, providing peace of mind throughout the entire project.

Moreover, professional providers understand the importance of proper planning, project management, and attention to detail. They can assess your specific situation, identify potential challenges before they become problems, and develop comprehensive solutions tailored to your unique requirements and budget constraints.

Why Darwin-Based Steel Manufacturers Makes Sense

Choosing local steel manufacturers providers in Darwin offers numerous distinct advantages that can significantly impact both your immediate experience and long-term results. Local professionals possess intimate knowledge of the area, deeply understand regional requirements and conditions, can respond quickly to your needs, and often provide more personalized service than larger, non-local companies.

One of the most compelling benefits of working with local professionals is their genuine commitment to building and maintaining their reputation within the community. When you choose Steel Manufacturers Darwin providers who operate locally and serve the Darwin community, you’re working with businesses that depend heavily on word-of-mouth recommendations, positive reviews, and repeat customers. This creates strong motivation to deliver exceptional service consistently and to go above and beyond to ensure client satisfaction.

Local businesses also have comprehensive understanding of the specific challenges, opportunities, and characteristics unique to Darwin. They’re intimately familiar with local suppliers and can often secure materials more quickly and cost-effectively. They understand regional weather patterns and seasonal considerations that might affect project timing or methodology. They’re experienced with common issues that arise in the area and know the most effective solutions for addressing them.

Additionally, local providers are typically more accessible and responsive. They can visit your site quickly for assessments or consultations, respond promptly to questions or concerns, and provide ongoing support after project completion. This accessibility and responsiveness can be particularly valuable when time-sensitive situations arise or when you need expert advice on related matters.

Essential Factors for Selecting Steel Manufacturers Providers

When searching for professional steel manufacturers in Darwin, several critical factors should guide your evaluation and decision-making process. Taking the time to carefully assess potential providers against these criteria will help ensure you select a professional partner capable of delivering the quality results you expect and deserve.

First and foremost, always verify that any provider you’re considering holds all appropriate licenses, certifications, qualifications, and comprehensive insurance coverage. This isn’t just a formality—proper licensing demonstrates that the provider meets professional standards and regulatory requirements, while adequate insurance protects you from liability should anything unexpected occur during the project. Don’t hesitate to ask for proof of these credentials and verify them independently if necessary.

Experience and track record matter significantly in this industry. Look for providers with substantial, verifiable experience specifically in Darwin and ask for references or examples of previous projects similar to yours. Experienced professionals have encountered and successfully navigated various challenges, developed efficient problem-solving approaches, and refined their techniques to consistently deliver quality results. They’re better equipped to handle unexpected situations and provide realistic timelines and cost estimates.

Communication skills and transparency are also crucial indicators of a quality provider. The best steel manufacturers professionals will clearly explain their processes and methodologies, provide detailed, itemized quotes with no hidden fees, keep you informed throughout every stage of the project, and make themselves readily available to answer questions or address concerns. They should demonstrate genuine interest in understanding your specific needs and goals, and be willing to discuss various options and their respective advantages or limitations.

Understanding the Investment in Quality Steel Manufacturers

Cost naturally represents an important consideration when hiring professional steel manufacturers providers, but it’s essential to look beyond simple bottom-line pricing and consider the overall value proposition you’re receiving. While budget constraints are real and valid, choosing solely based on the lowest price often proves to be a false economy that can lead to disappointment, additional expenses, or even safety concerns.

In the Darwin market, pricing for steel manufacturers can vary considerably based on numerous factors including project scope and complexity, materials and equipment required, timeline expectations, and the provider’s experience level and reputation. Reputable, established providers will offer transparent pricing structures and provide detailed, comprehensive quotes that clearly break down all costs and explain what’s included. Be wary of quotes that seem unusually low, as they may indicate corner-cutting, hidden fees, or inexperience.

Investing appropriately in quality steel manufacturers typically saves money over the long term by avoiding costly mistakes, ensuring work is completed correctly the first time, providing durable results that won’t require frequent repairs or premature replacement, and preventing potential safety issues or regulatory violations. Quality work often comes with warranties or guarantees that provide additional protection and peace of mind.

Conclusion

Finding the right steel manufacturers provider in Darwin requires thoughtful consideration and due diligence, but the effort invested in this process is undoubtedly worthwhile. By focusing on key factors like experience, reputation, proper credentials, and quality of service rather than price alone, you can ensure excellent results that meet your needs and exceed your expectations.

Take the time necessary to thoroughly research your options, ask detailed questions, verify credentials and references, and trust your instincts about which provider feels like the right fit for your project. The best steel manufacturers professionals will welcome your questions, demonstrate their expertise through knowledge and past work examples, and make you feel confident in their ability to deliver outstanding results.

Remember that choosing quality steel manufacturers represents an investment in your property, your safety, your satisfaction, and ultimately your peace of mind. Make your decision wisely based on comprehensive evaluation rather than hasty judgment, and you’ll enjoy the benefits of professional, reliable service for years to come.

Location: Darwin